BS-42

BS 42 is a hydraulic system, automatic, PLC controlling machine with 100 - 160 bar pressure range which the main machine and the batching plant is controlled by PLC.

Product picking robot is used in this facility. For this reason the products which are produced needs to be dried longer time and the quantity of wooden pallets should be thought according to this situation.

There is also options to carry the products with forklift or automatic system robot carrying cars. The batching plant which is used for dry mortar can also be used for wet mortar as a second option.

- A + (A Plus) energy saving products

- EFF3 class electric motors

- Free spare parts with machine

- 2 +2 total of 4 years warranty

- ISO 9001: 2008 total quality management system of conformity

- CE declaration of European standards

- Trained staff and "HL" product models

- Fast service, spare parts guarantee

- Appropriate material usage in the norms of DIN and TSEK standards

- Easy usable program selection

- Auto/Manuel Choice

- Authorization certificate at the end of training period

- Stop, standby and continue production from the point where was left.

BS-42 Technical Specifications

MAIN VALUES OF THE MACHINE

| Production Capacity | 130 - 140 Pallet per hour |

|---|---|

| Pallet Size | 1.400 x 1.350 x 230 mm |

| Control | PLC Automation System (Schneider) |

| Hopper Capacity | 1.8 m³ |

| Hydraulic Oil Capacity | 600 lt |

| Upper Vibration | 3 kW x 2 |

| Lower Vibration | 4 kW x 4 |

| Total Electricty Capacity | 300 kW |

| Total Vibration Force | 30.000 |

| Maximum Product Height | 3.000 mm |

| Maximum Product Weight | 600 mm |

| Machine Chassis Frame | 10 mm |

| System of Vibration | Classic Belt and Pulley Vibration |

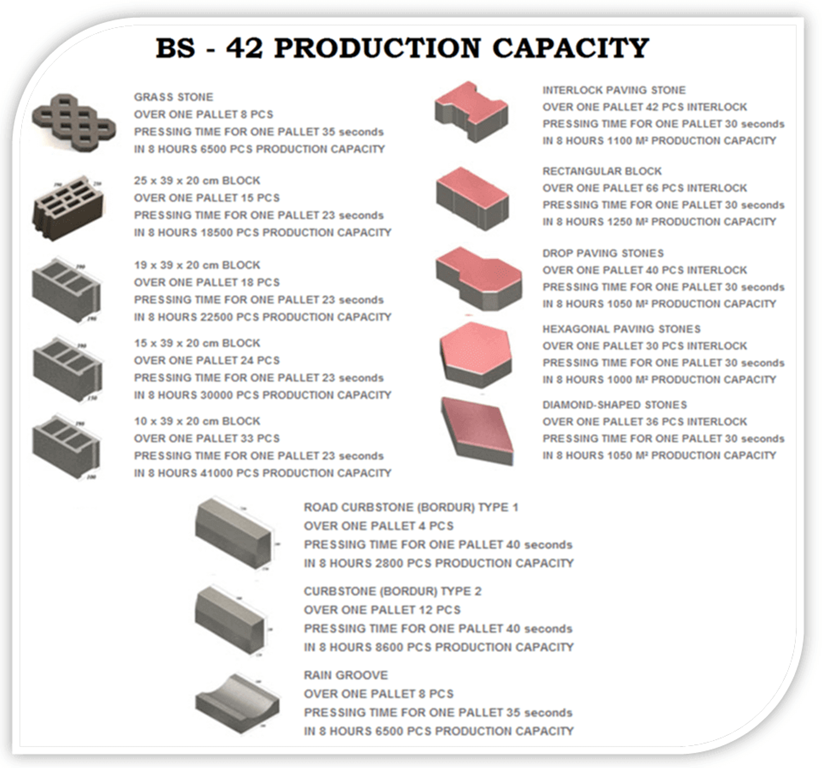

| Estimated Production Capacity in 8 Hours |

20 x 40 x 20 Block – 18.000 pieces Interlock – 40.000 pieces |

| Pressing Amount Per Press |

20 x 40 x 20 Block – 18 pieces Interlock – 42 pieces |

STACKING SYSTEM ROBOT

| Stacking Layer | 5 - 7 Row |

|---|---|

| Cleaning Brush | Present |

| Back Dry Product | Hydraulic Driver |

WOOD PALLET

| Pallet Size | 1.400 x 1.350 x 230 mm |

|---|---|

| Square Steel Thickness | 4 mm |

| Leg Thickness | 3.5 mm |

DRY PRODUCT CUBING ROBOT

| Pump Power | 7.5 kW, 40 lt/min |

|---|---|

| Profile Propulsion Power | 3 kW, 150 rpm |

| Rotational Power | 1.1 kW, 22 rpm |

| Chassis | 100 x 150 x 5 |

BS-42 Gallery

You can examine some photos of the product named BS-42 taken in our established facilities. For detailed information and references, you can contact our sales team by calling back or filling out the request form.

Transport

Shipping friendly equipments of our concrete block plants minimize the transport cost of our clients with its modular structure and availablity to be shipped within closed truck trailers and containers.

BS-42 Video

BS-42 General Layout

REQUEST FORM

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR