BS-36

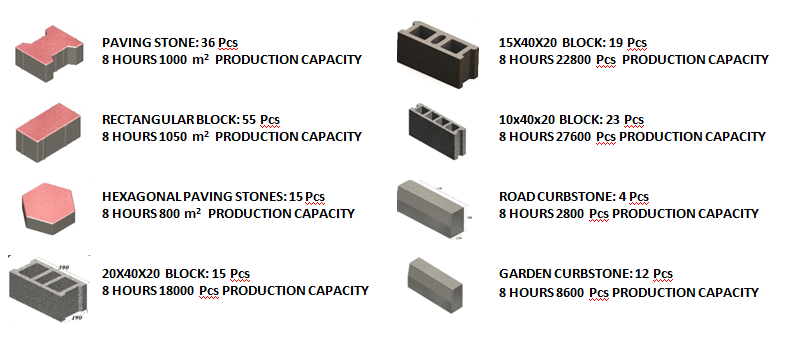

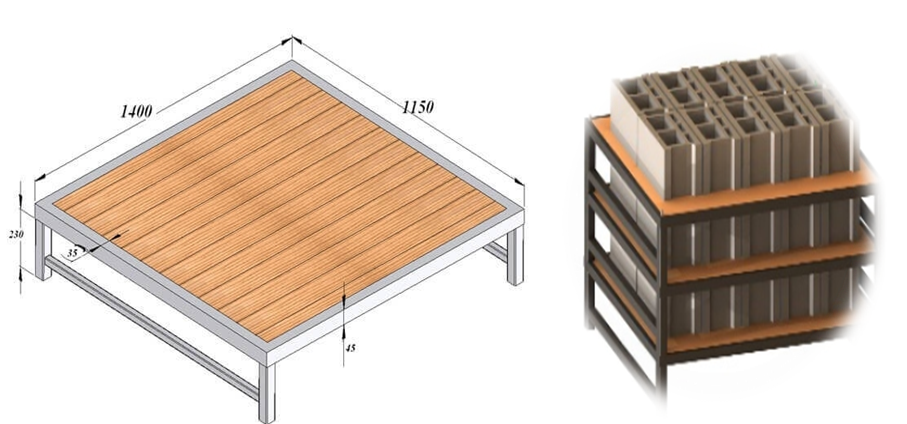

These machines operate on a hydraulic system within a pressure range of 120-150 bar. This machine produces 15 Pcs of blocks of size 20×40×20 cm and 36 Pcs of paving stones in each pressing cycle. Wooden pallets are used for production.

The concrete is pressed into the molds and then pressed onto the pallets. Products produced in the same manner are left to dry on the production wooden pallets.

The control panel developed by CONSTMACH engineers ensures ease of machine operation through sensors. The automation system allows for daily production storage. The control panel is user-friendly and provides the necessary timing for different types of blocks and paving stones.

Machine and Company Features:

- A+ (A Plus) Energy-saving products

- EFF3 Class electric motors

- Free spare parts with the machine

- CE Declaration for European standards

- Use of materials compliant with DIN and TSEK standards

- Easy-to-use program selection

- Automatic/Manual selection

- Stop, wait, and resume production from where the machine stopped

- Forklift option available

- Troubleshooting via online remote option

- Compliance with low voltage directives

- Use of safe brand raw materials

- Trained personnel and "HL" product models

- Fast service and 2-year Machine and spare parts warranty

- 7/24 pre-sale and after-sale service

- Certification at the end of the training period

PRODUCTION CAPACITY OF BS 36

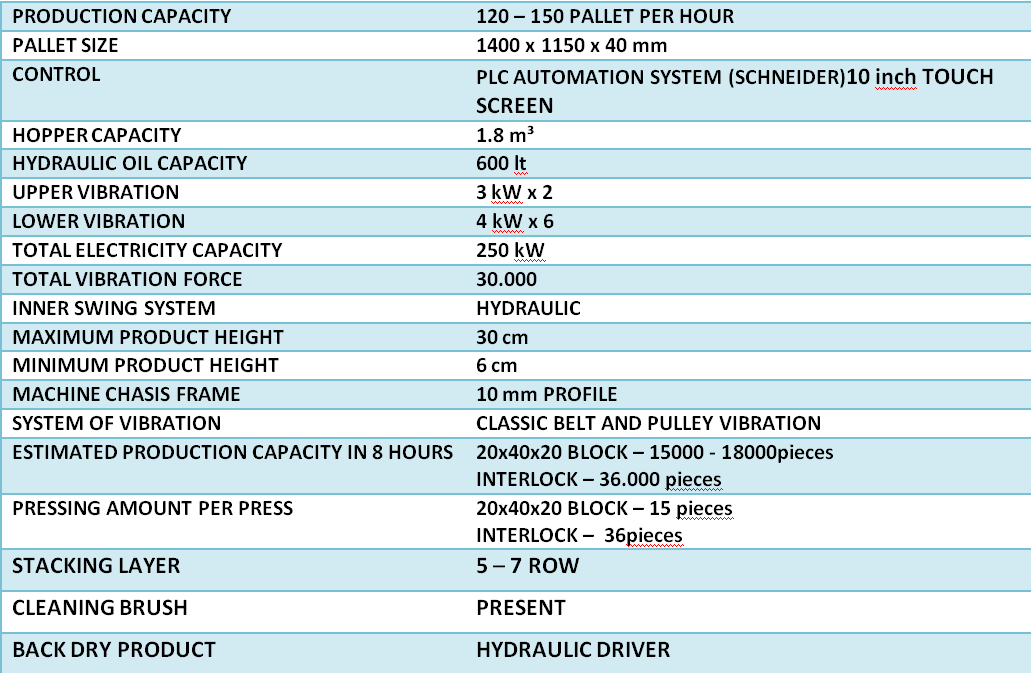

BS-36 Technical Specifications

MAIN VALUES OF THE MACHINE

SHAPE AND DIMENSIONS OF WOODEN PALLETS FOR PRODUCTIONS:

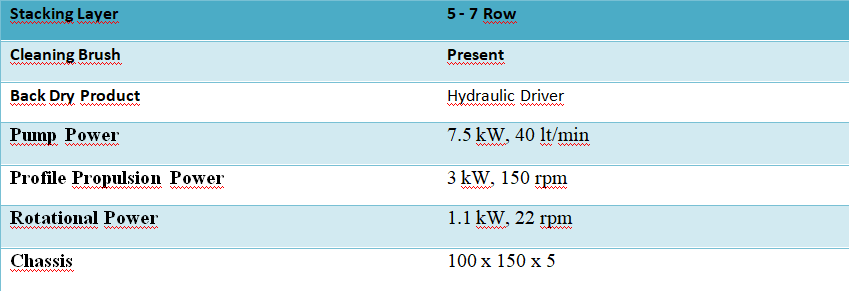

DRY PRODUCT CUBING ROBOT

BS-36 Gallery

You can examine some photos of the product named BS-36 taken in our established facilities. For detailed information and references, you can contact our sales team by calling back or filling out the request form.

Transport

Shipping friendly equipments of our concrete block plants minimize the transport cost of our clients with its modular structure and availablity to be shipped within closed truck trailers and containers.

BS-36 Video

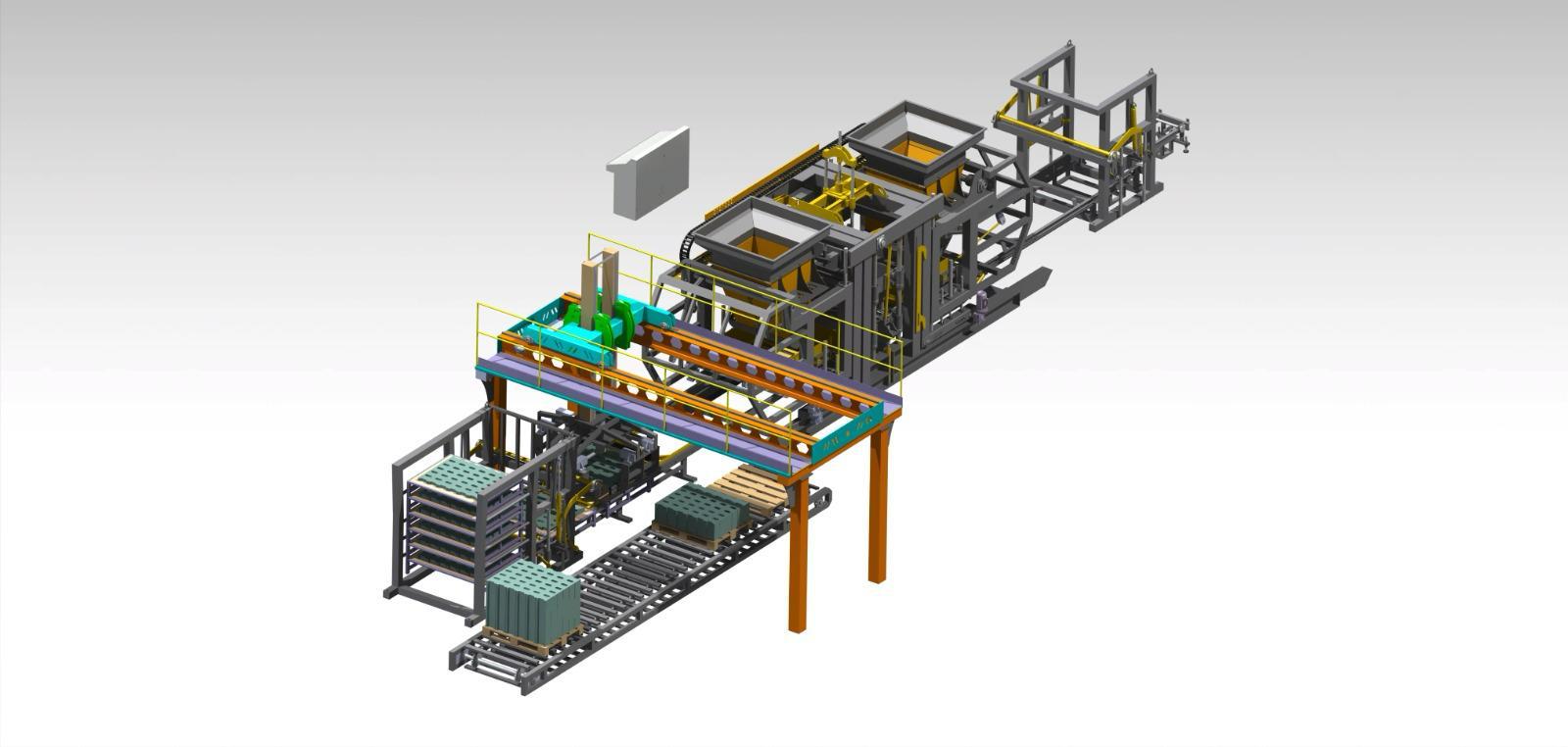

BS-36 General Layout

REQUEST FORM

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR