CONSTMACH JC-3 Mobile Crushing & Screening plant is a perfect solution for crushing and screening very hard rocks with high abrasiveness and Silica (SiO2) ratio such as granite, basalt, gabbro etc.

JC-3 is the result of advanced design and engineering, usage of high quality materials and parts with long-lasting and premium craftsmanship.

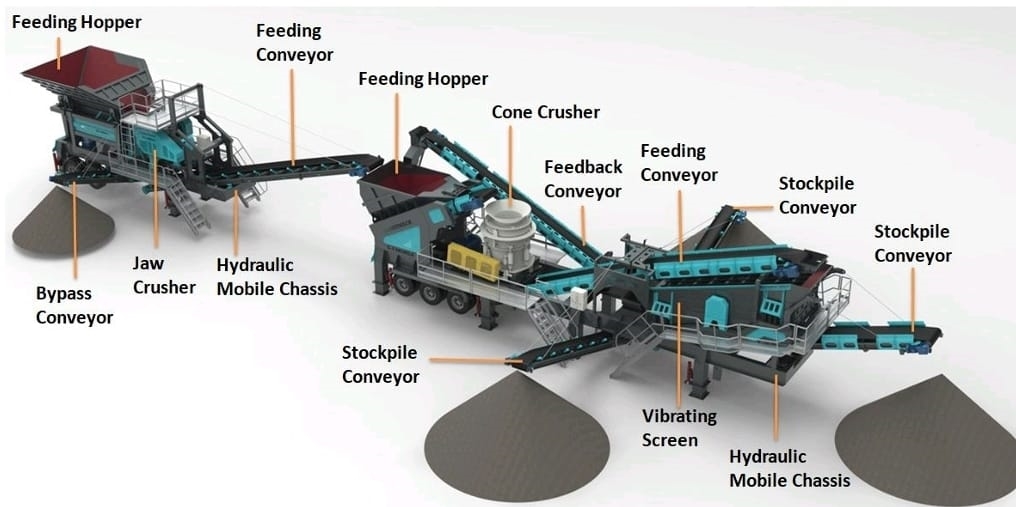

JC-3 Mobile Crushing & Screening Plant includes double chassis and it is combination of:

1st chassis:

- Feeding Hopper with vibrating feeder

- CJC-110 Primary Jaw Crusher

- By-pass conveyor (for extraction of soil)

- Feeding Conveyor

- Automation System with PLC and remote controller for whole system

- Dust Removing System

2nd chassis:

- Feeding Hopper of Cone Crusher

- Feeding conveyor between hopper and cone crusher

- Cone Crusher, METSO HP 300 or equivalent

- Vibrating Screen with 3 or 4 decks

- Feedback Conveyor from vibrating screen to cone crusher

- Fold-up type Stockpile Conveyors

- Wheeled mobile chassis with hydraulic legs

- Automation System with PLC and remote controller for whole system

- Dust Removing System

- Diesel Electric Generator Set (Optional Application)

JC-3 production capacity is between 250 to 300 tph according to hardness grade of the material to be crushed. Maximum feeding size is 1.100 x 850 mm. The cone crusher is Metso HP 300 or equivalent model. It is possible to get 3 or 4 different fractions at the same time. In case of needing for increasing the fine material ratio and/or having more cubical product, the plant is equipped with our V-90 mobile sand making plant which includes a VSI crusher. In that case the overall configuration is called as JCV-3.

In case of need, it is possible to adapt an electric generator to chassis of the plant.

JC-3 is a user-friendly combination which promises easy mount/assemble features to its operators. The plant can be put into use in very short time. In case of need, it is possible to equip the feeding hopper and stock conveyors with hydraulic opening mechanism and in that case the plant can be taken to operation without needing any external equipment such as crane, loader etc.

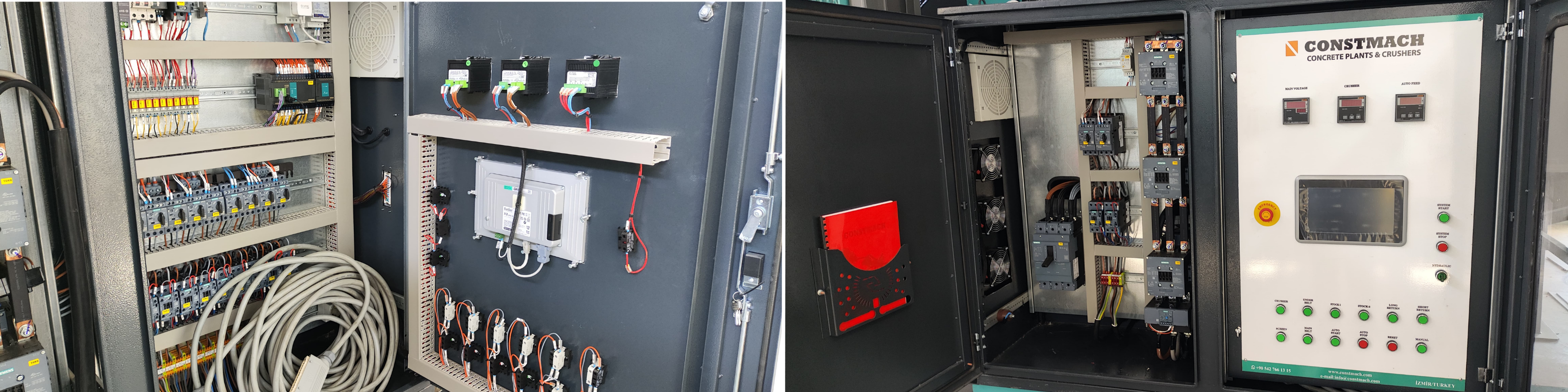

JC-3 is equipped with high-tech automation system including top class SIEMENS – SCHNEIDER brand electronic components and PLC. JC-3 is operated by just a tablet controller.

Overall dimensions of both chassises of JC-3 are determined according to international road transport regulations and it is transported between jobsites easily.

| Production Capacity | 250-300 tph |

|---|---|

| Maximum Feeding Size | 1.100 x 850 mm |

| Main Configuration | Primary Jaw + Secondary Cone + Vibrating Screen |

| Total Motor Power | 450 kW |

| Electric Generator Requirement | 800 kVA |

| Weight of the plant | 100.000 kg |

| Sizes of the plant | 1st chassis: 13(L) x 3.4(W) x 4.5(H) meters 2nd chassis: 20(L) x 4.4(W) x 4.5(H) meters |

| Chassis Type | Double chassis on wheels, equipped with hydraulic opening legs. |

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR