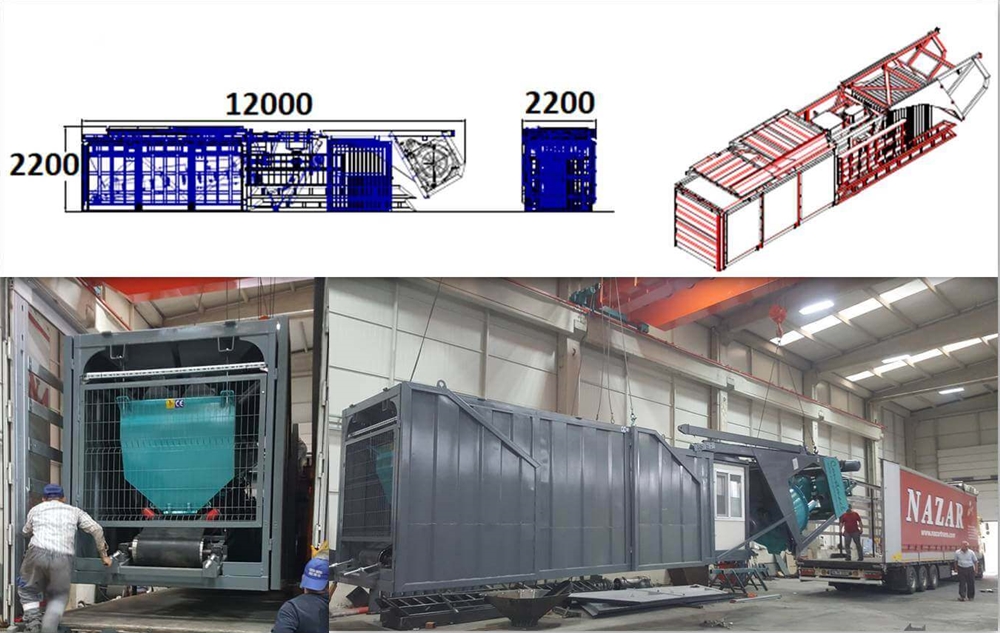

CONSTMACH COMPACT 30 full automatic concrete batching plant is a specially designed concrete plant model which can be transported within only 1 unit tractor-trailer or 40 ft. OT container and that’s why it is called as also CONTAINER TYPE concrete plant. COMPACT 30 is preferred especially in cases of the area to be installed has limited dimensions.

With its easy portability and rapidly installable design and necessity of minimum infrastructure investment, COMPACT 30 compact type concrete plant offers economic advantages to its users. COMPACT 30 is designed and manufactured in accordance with CE standards.

COMPACT 30 Concrete batching plant requires a minimum site preparation. Just a flat concrete that is capable to carry the total load of the plant is enough. Cement silos that are supplied with the plant have full steel legs to remove the necessity of concrete legs building by the client. Thanks to the metal walls that are present at both sides of the plant, aggregates filling ramp can be prepared easily without constructing a concrete wall.

Single shaft, pan or planetary type mixers can be used in COMPACT 30 concrete plant so that it could be used for different purposes such as ready mixed concrete, dry mixed concrete, precast concrete production etc.

COMPACT 30 is equipped with high-tech automation system including top class SIEMENS – SCHNEIDER brand electronic components and PLC. The whole system is controled through an advanced sofware which is sophisticated features and user friendly interface.

MAIN VALUES OF THE PLANT

| Production Capacity | 30 m³/h |

|---|---|

| Sizes in Transport Position | 12(L) x 2.2(W) x 2.2(H) meters |

| Weight | 13.000 kg |

| Total Motor Power | 55 kW |

| Required Electric Generator | 80 kVA |

| Mixer Options | Pan – Single Shaft - Planetary |

| Required area to operate | 200 m² |

TECHNICAL SPECIFICATIONS

| Aggregate Hopper Volume | 4 x 6 m³ |

|---|---|

| Aggregate Weighing Hopper | 0.75 m³ |

| Aggregate Weighing Conveyor | 600 x 4.000 mm |

| Skip Hoist Bucket Volume | 0.75 m³ |

| Mixer Wet Concrete Volume | 0.5 m³ |

| Cement Weighing Hopper | 300 kg |

| Water Weighing Hopper | 200 lt |

| Additive Weighing Hopper | 10 lt |

| Air Compressor | 300 lt, 5.5 kW |

| Cement Silo | Optional from 50 to 200 tonnes capacity. |

| Control Type | FULL AUTOMATIC |

EN

EN TR

TR EN

EN ES

ES FR

FR RU

RU RS

RS AR

AR